By Vinipul Chemicals Pvt. Ltd., Mumbai – ISO, FSSAI, GMP Certified Manufacturer & Exporter

🔍 Introduction: Why Phenol Still Matters in Modern Material Science

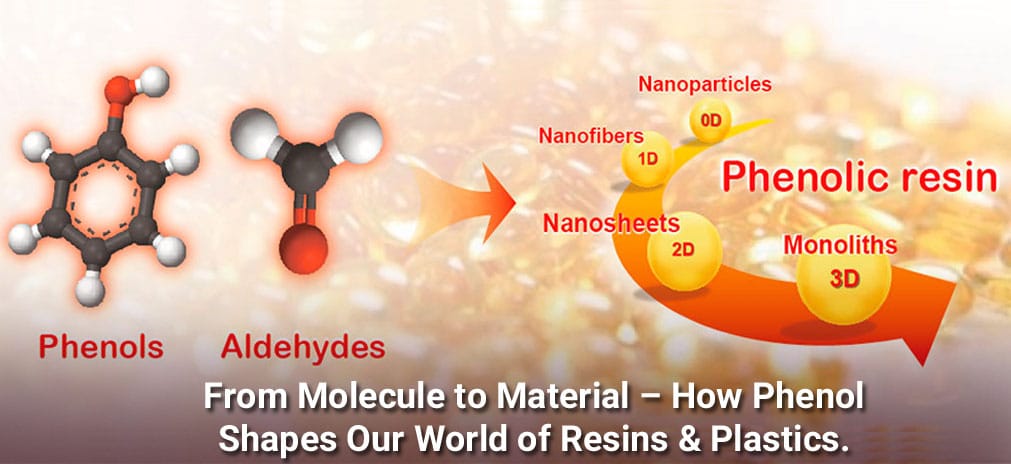

In a world constantly innovating with polymers, composites, and engineering plastics, phenol remains a core building block behind some of the most durable, heat-resistant, and electrically stable materials. Whether you’re holding an electrical switch, using a kitchen countertop, or operating industrial machinery—phenol-derived resins are likely involved.

While often overshadowed by buzzwords like “BPA-free” or “polycarbonate,” phenol-based chemistry powers the foundation of everything from adhesives and laminates to aerospace-grade plastics. This blog explores how phenol plays an irreplaceable role in the global resin and plastic industry, and how Vinipul Chemicals Pvt. Ltd. delivers high-purity phenol products to meet diverse industrial needs.

🔬 What is Phenol? (And Why is it So Reactive?)

Phenol (C₆H₅OH) is a white crystalline solid or clear, slightly yellow liquid at room temperature, with a distinct sweet odor. It consists of a benzene ring bonded to a hydroxyl group, making it aromatic, acidic, and highly reactive—especially with formaldehyde and other electrophiles.

Key properties include:

- Molecular Formula: C₆H₅OH

- Melting Point: ~40.5°C

- Boiling Point: ~181.7°C

- Solubility: Slightly soluble in water, highly soluble in alcohol and ether

- CAS Number: 108-95-2

These traits allow phenol to serve as a precursor for complex polymerization reactions, especially in the production of phenolic, epoxy, and polycarbonate resins.

🧱 Why Phenol is Essential in Resin & Plastic Chemistry

Phenol’s real magic lies in its reactivity with aldehydes (like formaldehyde) and carbonyl compounds. This makes it the cornerstone for high-performance resins, capable of withstanding:

- Extreme temperatures

- High electrical loads

- Abrasive environments

- Chemical exposure

Here’s why industries still rely on phenol today:

- 🔩 Thermal Stability: Phenolic resins don’t melt or deform easily

- ⚡ Insulation Strength: Used in switches, circuit boards, and transformers

- 💪 Adhesion and Bonding: Essential in plywood, laminates, and abrasives

- 🛡️ Chemical Resistance: Ideal for coatings, tanks, and pipe linings

🧰 Applications of Phenol in Resin and Plastic Production

Below are the top material classes that depend on phenol:

1. Phenol-Formaldehyde Resins (PF):

Used for manufacturing electrical insulators, brake linings, particle boards, and heat-resistant parts. PF resins are rigid, durable, and have excellent flame resistance.

2. Bisphenol A (BPA) for Polycarbonate Plastics:

Phenol reacts with acetone to create BPA—a critical compound in polycarbonate plastics and epoxy resins. These are widely used in:

- Optical discs (CDs/DVDs)

- Bulletproof glass

- Water bottles

- Automotive panels

- Medical equipment housings

3. Epoxy Resins:

When phenol is transformed into BPA, it’s further used in epoxy formulations found in:

- Industrial coatings

- Adhesives

- Electronic encapsulations

- Marine and aerospace composites

4. Alkylphenols in Surfactants & Additives:

Derived from phenol, nonylphenol and octylphenol serve in manufacturing plasticizers, detergents, and emulsifiers.

5. Caprolactam for Nylon:

Phenol is indirectly involved in the Beckmann rearrangement process to produce caprolactam, the base for Nylon-6.

🧪 Vinipul’s Phenol Offerings – High Purity. Industrial Ready.

At Vinipul Chemicals Pvt. Ltd., we supply technical and industrial-grade phenol tailored for resin and polymer manufacturers. Our Mumbai-based facility and Taloja MIDC factory are fully equipped for bulk deliveries and export logistics.

Available Grades:

- Phenol Technical Grade – 99% min purity

- Phenol Crystal (Solid form)

- Phenol Liquid – Bulk Tanker

- Customized formulation for epoxy and PF resin manufacturers

📊 Technical Specifications of Phenol

| Property | Specification |

|---|---|

| Chemical Name | Phenol |

| CAS No. | 108-95-2 |

| Molecular Formula | C₆H₅OH |

| Purity | 99% Min |

| Appearance | White Crystals / Clear Liquid |

| Boiling Point | ~181.7°C |

| Melting Point | ~40.5°C |

| Solubility | Partially soluble in water |

| Grade Available | Technical Grade |

| Packaging | 25 kg bags, 200 kg drums, bulk |

✅ Compliance, Certifications & Safety

Vinipul Chemicals Pvt. Ltd. ensures strict compliance with:

- ✅ ISO 9001:2015

- ✅ FSSAI (For food-grade intermediates when applicable)

- ✅ GMP Certified Production Facility

- ✅ GHS-Compliant Safety Data Sheets

- ✅ Hazard Classification: Toxic, Flammable – Handle with PPE

- ✅ REACH-Ready Export Documentation

MSDS, COA, and third-party test reports are available on request.

📦 Packaging & Delivery Options

We offer customizable packaging based on your manufacturing or distribution needs:

- 🔹 25 kg HDPE Bags (Solid Phenol)

- 🔹 200 kg UN-approved Drums

- 🔹 Bulk Tanker Load (Liquid Phenol)

- 🔹 Export Palletized Containers with Anti-Leak Lining

Logistics support from Mumbai port to all global regions.

🌍 Industries We Serve

Phenol supplied by Vinipul Chemicals is widely used in:

- ✅ Resin & Polymer Manufacturers

- ✅ Adhesive & Coating Industries

- ✅ Circuit Board & Electronic Insulation Firms

- ✅ Laminated Board, Plywood & MDF Manufacturers

- ✅ Composite and Aerospace Component Suppliers

- ✅ Plasticizer and Intermediate Chemical Plants

🗣️ Voice Search Optimized FAQs (SEO + AEO + LEO)

What is phenol used for in plastic production?

Phenol is used as a base chemical to make epoxy resins, polycarbonate plastics, and phenol-formaldehyde resins, which are essential in electronics, automotive parts, and coatings.

Is phenol safe to use in manufacturing?

In controlled environments with PPE, phenol is safe for industrial use. Vinipul Chemicals provides MSDS and handling guidelines to ensure safety.

What grade of phenol is used for epoxy resin?

Typically, high-purity technical grade phenol is used to manufacture Bisphenol A, which is further used in epoxy resins.

Does Vinipul Chemicals export phenol outside India?

Yes, we export phenol globally with all documentation, REACH-compliance, and packaging for sea/air shipments.

What is the purity of phenol offered by Vinipul Chemicals?

We supply 99% min pure phenol, with consistent batch quality and full COA support.

Can phenol be customized for specific resin applications?

Yes. Our R&D support allows formulation customization for clients in PF resin, epoxy, and plastic additive segments.

📞 Ready to Source Industrial-Grade Phenol?

Vinipul Chemicals Pvt. Ltd. is a trusted name in phenol supply and distribution. With ISO/GMP-certified facilities, custom packaging, and global logistics—we ensure consistent, compliant, and cost-effective delivery.